I’ve got a lot of rusty old tools lying around here that I thought were a reasonable winter project to clean and restore. So the first thing was to clean off the heavy “crust of rust” on them and the easiest way to do this is with an electrolysis bath. This is how it works and what you’ll need to do this by yourself. It’s cheap, easy and effective.

The idea behind this the so called “Electrolysis”, which means literally, “dissolving by electricity”. So what we want to do is to (at least partially) dissolve the topmost layer of (oxidised) material on our workpiece – which is, in our case, rust. Now simply spoken, this is done by running an electric current through a conductive solution and thus removing material.

Not so simply spoken: An electrical current produces a lack of electrons on the positive terminal (“anode”) and an abundance of electrons on the negative terminal (“cathode”), thus electrons will wander through our conductive liquid from “minus” to “plus” – doing the job of loosening material on the cathode and heavily decomposing the anode. One could say it’s “turbo-rusting” the anode (thus: “sacrificial anode”). For deeper investigation, as usual wikipedia.

Paraphernalia:

- A car battery charger (mine is 12 V with 0.6 A – which is fairly enough)

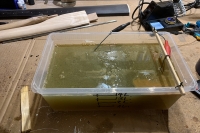

- A plastic container, large enough to contain your piece of metal

- A piece of scrap metal as sacrificial anode (see below)

- Thick wire (I used a wire coat hanger)

- Sodium carbonate (“Natron” in german), not Sodium bicarbonate (as in baking powder)

- Table salt

- Water

(see images)

- Fill your tank with water

- Add one heaping tablespoon of “Natron” and one heaping tablespoon of salt per 5 liters of water (this is not exact science) and stir to dissolve thoroughly. This is to make the water more conductive.

- Now find a way to attach your sacrificial anode to the tank. Make sure the connection point is outside of the liquid (otherwise your connection clip will dissolve 🙂 )

- Insert your workpiece, as well firmly attached to some sturdy wire protruding from the liquid.

- The two pieces should be close together but not touching each other (short circuit!)

- Connect positive to your anode and negative to your workpiece and give it time for up to one night. Ventilate the area, because various gases will be produced during the process.

- Next day, disconnect everything and scrub off the loosened rust under running water with some steel wool.