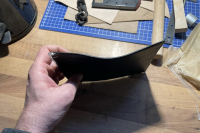

I stumbled across an article on a special type of a traditional japanese hatchet, the “Nata“. It derives from the use as a garden tool, but it seems to also gain increasing popularity in the bushcraft and knifemaker scene. I liked the form and the unpretentious design and wanted to try my own version.

Rotary Tumbler Contraption

I made a rotary tumbler device for metal cleaning (mainly knife blanks) from stuff I had in the shop. The goal is to somewhat “polish” the metal before further treatment. It’s made of a 12V-Motor, some scrap wood and a wine bottle tube.

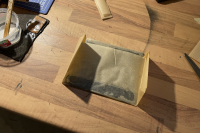

Even more Micarta

I made another plate of homegrown micarta. This time in red – afaik, the fabric was a window curtain in its former life. Since it says „back to the grindstone“ for me these days, I wonder when I might be able to put it to use 🙁

Making Micarta – Test II

So after another test fabricating micarta I grabbed the first one again and lo and behold: After 48 hrs more curing time it has become hard and durable! Mental note: The thicker the material the more time needed to cure (who would have thought?) and the specification on the package was just plain wrong.

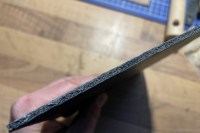

New Bevel Grinding Jig DIY

Without further a do, my bevel grinding jig for knife making just … disappeared … (somehow, things in my shop seem to have a tendency for that when I’m around…). So I made a new one, this time from aluminium, since it’s simply easier to work on for me.

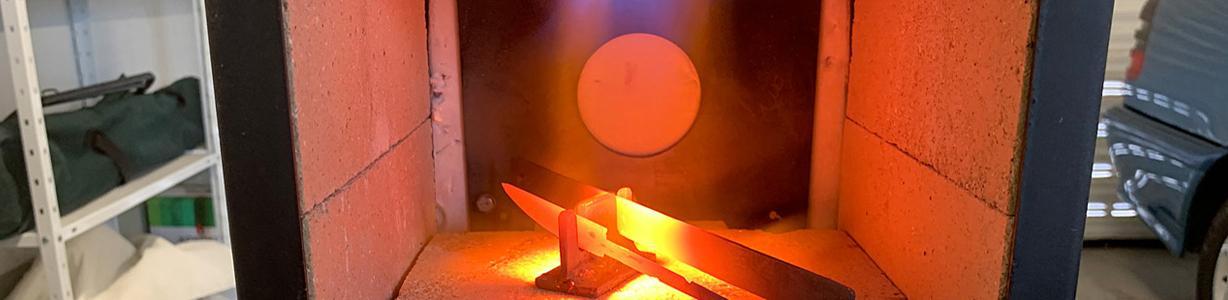

Blacksmithing Course, Part II

So, today I took my second part of the blacksmithing course at Schmiede Bötersheim. Again it was absolutely great, but:

I could kick myself in the a** so much…

I didn’t pay enough attention for a moment and let a thin part of the poker I’m working on get too cold while hammering it, which made it brittle and weak at that point. Grinning knowingly as well as indulgently, the blacksmith stated that’s a really common beginner’s fuckup and she welded it safe in seconds 🙂

At least I’m learning and (hopefully) I’m improving.

Blacksmithing Course, Part I

I was gifted a beginner’s blacksmithing course for christmas way back in 2019 by my (deeply beloved 🙂 ) wife. Unfortunately, due to Corona it couldn’t take place for almost two years, but now I was finally able to take part.

IT WAS FRIGGIN’ AWESOME!

I recommend everyone (even if only slightly) interested in blacksmithing take such a course. It’s an eye-opener, it’s loads of fun and it gives a great feeling of achievement. Ahhh… and yes, of course, you also LEARN exponentially along the way. I’m so hooked right now.

All Categories:

- Common (77)

- DIY Projects (161)

- Fire & BBQ (50)

- Garden & Growing (49)

- Knife making (40)

- Recipes & Kitchen (247)

All Tags:

Chickens & Pets · How Tos · Lada Niva · Manly Hints · Nice to Know · Plans & Info · Prepping · Reading · Reviews & Products · Sticky · Travel

I’m (somewhat) social, too!