I made a tang hole filer for my next knife project to come. Just drilling and working with a needle file is not very satisfactory. I used a jigsaw blade that I trimmed down a little, some scrap wood and a dab of epoxy glue. Done.

Tutorial: Knife Care with a Sharpening System

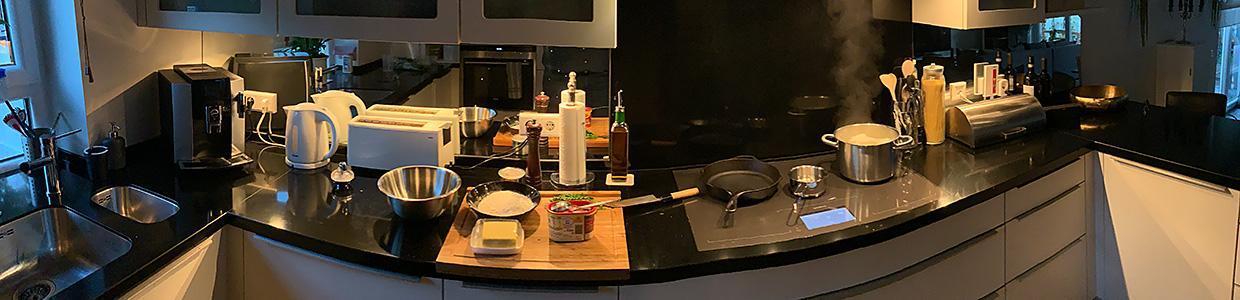

I had a friend of mine over these days with two well-used and now dull knives – this inspired me to write this article. At a certain point of knife usage, just honing a blade’s edge won’t do the job anymore and you will have to re-sharpen your knife and give it a nice clean edge again.

This is how I do this with all my knives, kitchen or outdoor, in this case using a Lansky knife-sharpening-system (which I know is discussed controversially on the internet). With a little training and devotion you can achieve excellent results with it – and in a much easier way than with a traditional whetstone. This is my way to do it and it works absolutely satisfying for me.

Japanese Box Bellows

I was fascinated by a japanese blacksmith’s video where this guy was working with a (seemingly) traditional two-stroke box bellows, and as things worked out, my hairdryer that I used as a blower for my coal forge recently bit the dust. So the mission was clear, I wanted to make such a cool box-bellows-contraption myself. After doing some internet research, here’s what I did and what I used:

Outdoor-/Fishing Knife Done

I finally finished my Outdoor-/Fishing Knife that I was working on for so long this time. See previous posts #1, #2 and #3 if you like. It’s made from 3 mm 90MnCrV8 steel (type 1.2842), hardened at ~830 °C, quenched in oil and annealed for two hours at 210 °C in the oven. The scales are mahagoni with a cutout for the glass breaker at the end of the handle.

Outdoor-/Fishing Knife Progress

Due to some… ahhh… “peak” in workload over the last few days, I didn’t have the time to dedicatedly work on the new knife very much. But after sanding the handle with 200 up to 600 grit sandpaper, I was finally able to apply the first coat of boiled linseed oil to it – more layers will follow. Next thing is cleaning and at least roughly polishing the blade and then – finally – sharpening. I find it looks great 🙂

See part one of the building process here if you like.

New Outdoor-/Fishing Knife in the Making

I finally found time to continue working on my long-planned new outdoor knife. I wanted to create a sturdy, yet slender multi purpose knife to carry with me when I go fishing or into the outdoors. Here are some images:

My Makeshift Simple Anvil

I got myself a piece of good old german steel railroad track from eBay to use for an anvil (you can find a shitload of videos on that topic on YouTube). So my simple construction consists of no more than a piece of a oak tree stem (left from last year’s round-up) and said railroad track piece, screwed tight with the meanest, thickest and longest screws I could find in the shop. Drilling the mounting holes was such a pain in the ass…

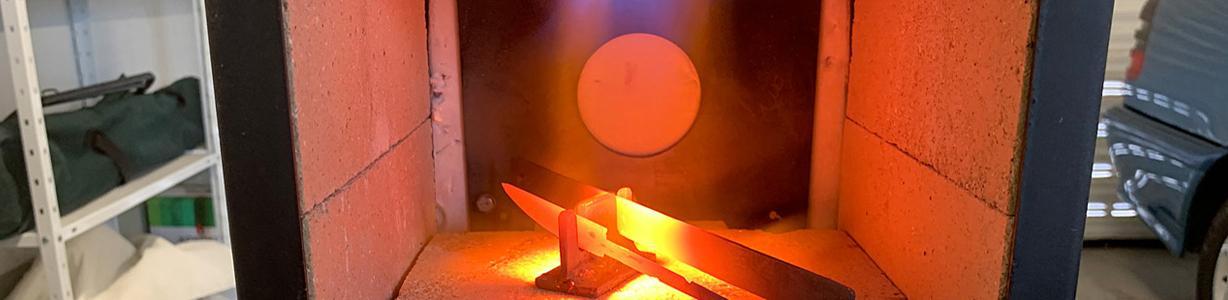

Gas Forge

I finally seized the opportunity to bring my gas forge back to life and try to harden some steel. It’s the predecessor of this Becma forge here and I can in good faith recommend it. I love the hissing sound and the bright colors.

All Categories:

- Common (77)

- DIY Projects (161)

- Fire & BBQ (50)

- Garden & Growing (49)

- Knife making (40)

- Recipes & Kitchen (247)

All Tags:

Chickens & Pets · How Tos · Lada Niva · Manly Hints · Nice to Know · Plans & Info · Prepping · Reading · Reviews & Products · Sticky · Travel

I’m (somewhat) social, too!