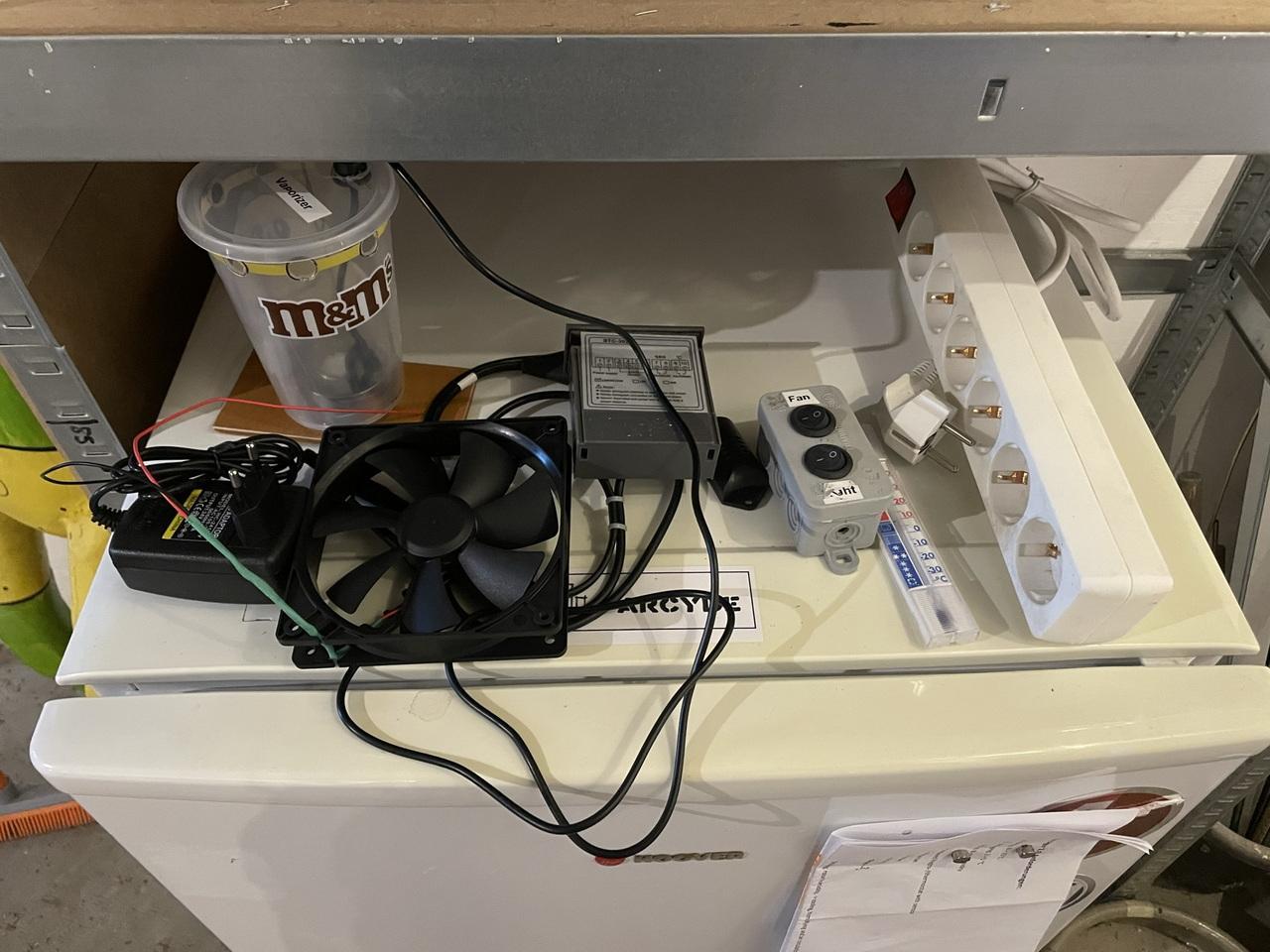

A new project begins! Unfortunately, the last dry aging chamber I made didn’t even see real action before the second hand fridge I used to build it put it’s feet up. I found another pre-used and reasonably prized one on eBay classifieds now and I want to try again.

To ease things up a little I will omit some of the functionality the first one was planned to have, but rather keep the option of upgrading it later. A materials list will follow as soon as I have an idea on how to implement everything in detail. So here’s the state of play so far:

Contemplated purposes/requirements:

- Dry Aging:

Dry aging temperatures should be as low as 2 – 5 °C with a rel. humidity of around 75 – 85%. - Dry Curing:

For curing, temperatures of 8 – 15 °C and a humidity of around 55 – 65% are recommended.

Resulting functionality:

First, a method of raising humidity levels will be necessary (as far as I’ve learned, lowering isn’t really a necessity), as well as effective temperature control.

Both of the above mentioned cases additionally call for sufficient air circulation in order to avoid stagnant damp air around the meat. This contributes to bad mold prevention and a more even drying. I’ll try to establish a selectively internal or external air flow.

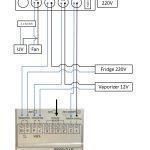

First wiring diagram:

I’ll be re-using the former ⤷ STC-3028 controller unit, it worked well and is easy to set up.

I’ll be re-using the former ⤷ STC-3028 controller unit, it worked well and is easy to set up.