I made a tang hole filer for my next knife project to come. Just drilling and working with a needle file is not very satisfactory. I used a jigsaw blade that I trimmed down a little, some scrap wood and a dab of epoxy glue. Done.

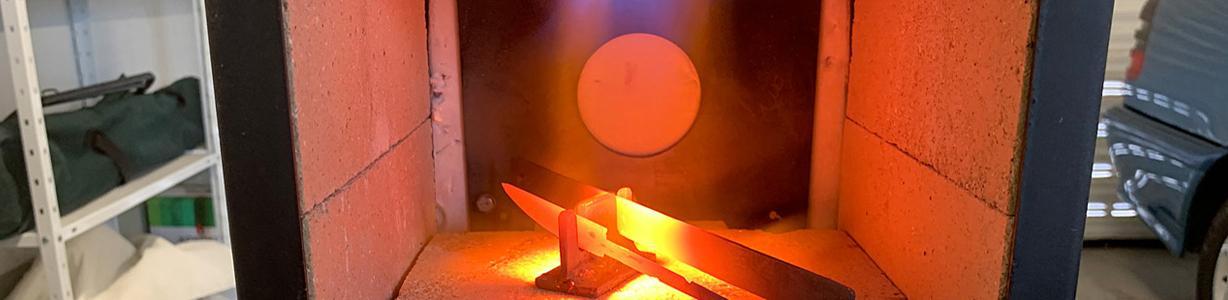

Homemade Tabletop Grill in Action

So we caught the weekly allowance of two hours of sunshine the german weather gave us today and used it to finally try out the tabletop grill. It works well and the insulation at the bottom is very effective – no particularly strong downward heat development, so it seems to be safe to use right at the table. Fotos:

Homemade Codsworth Cheese

Yay, my first cheese is ready! The Codsworth I made about a month ago is done ripening and ready to serve!

Yay, my first cheese is ready! The Codsworth I made about a month ago is done ripening and ready to serve!

I don’t know if everything I did went the correct way, and I certainly don’t know if it tastes even rudimentarily like a proper “Cotswold” since I never had one before. But it definitely is flavourful and – yes – even a little hearty. It does have a hint of a sourly note, not unpleasant but noticeable. It goes well with bread and salad and a drop of olive oil and some pepper also fit it well. I’ll also try it melted in some oven baking recipe.

Until now, nobody got a bad stomach from it and everybody found it at least pleasant enough 🙂

Cheesecurd Stirrer DIY

The last cheesemaking experiment seems to have worked out beautifully as far as I can see. But now, another recipe that I want to try calls for stirring the curds gently but consistently for 45 minutes straight – all my love for cheese aside, I won’t do that. That’s why I made a cheesecurd stirrer:

The principle is stolen from the concept of a wort stirrer for beer making that I knocked together years ago, but this time I wanted it not to stir circularly but to stir vertically. As you can see, the construction is easy, the motor is a 12V low-speed-motor from eBay, the rest is scrap from the shop.

The result can be admired above, I’m dying to try it in reality so I’ll have to go get some fresh milk next week 🙂

Cheese Making at Home

I got an ebook on cheese making for free recently, but honestly, I don’t think it was much of a highlight. Nonetheless, I tasted blood from it and additionally bought myself this book which is much more informative and educational (that guy has an awesome YouTube channel too).

Subsequently, I made a cheese press a couple of days ago and wanted to put it to use now. The first try was a “Cotswold” cheese (seems to be a region in southern great britain that I’ve never heard of before), but as an old Fallout 4 addict, of course I named my version “Codsworth” 🙂

DIY Cheese Press

This guy has too much free time at his hands… 🙂 I made a cheese press, because I was offered an eBook on cheesemaking – for free! Well, I like cheese in almost all of its forms, so I’ll try that out. Here’s how it was made and how it’s supposed to work.

Whetstone Holder

I figured my cooking knives deserved a little love after seeing rather heavy action in the last weeks. Since climbing stairs is not my favourite activity these days, I looked for a possibility to sharpen them properly in the kitchen, not downstairs in the shop. So behold Farcyde’s newest ingenious piece of engineering: My kitchen sink whetstone holder!

It took easily one whole hour to make it and another heaping 5 minutes for some protective oil coat! It’s taylor-made to fit into my kitchen sink snugly and to be on the safe side I also added an anti-slip pad under the whetstone and at the areas of support. One night of drying to let the oil set a little and it’s ready for use. A simple construction, the images speak for themselves.

Cider Making, the Second Stage

(This is part III of the cider making series. Read part I, part II and part IV here.)

It seems the primary fermentation has come to a halt do far, so it’s time to transfer everything into another vessel and let the secondary fermentation take it’s course. The correct english term for this seems to be “racking the cider off it’s lees”.

While the primary fermentation is about yeast cells converting sugar into alcohol and CO², the second fermentation is lactic acid bacteria converting malic acid into lactic acid and CO² and give the brew a smoother, less sour taste. It occurs naturally and spontaneously when the liquid is transferred to a storage container and the yeast is no longer the dominant microbiological species in the soon-to-be cider.

All Categories:

- Common (77)

- DIY Projects (165)

- Fire & BBQ (50)

- Garden & Growing (51)

- Knife making (40)

- Recipes & Kitchen (256)

All Tags:

Chickens & Pets · How Tos · Lada Niva · Manly Hints · Nice to Know · Plans & Info · Prepping · Reading · Reviews & Products · Sticky · Travel

I’m (somewhat) social, too!